We have all been in a meeting where miscommunication happens. One of the biggest challenges when dealing with analytics in business is that the more powerful the analytics, the harder it is to explain to other people not involved directly in the analyzing. Exactly how the analytics works and why the results should be trusted by our colleagues and leadership is a challenge. The same is true with product (or service) cost management—specifically, when using what are commonly called “should-cost models”, (models for estimating the cost of a product or service).

A big part of the communication problem is that there is not just one type of cost model. Cost management is a broad field with a variety of methodologies to address the almost infinite world of situations for which one wants to know the cost of manufacture or service delivery. Even if an executive has some understanding of one particular cost-modeling technique, it can often be confusing when the analytics team uses different technique.

This can lead to uncomfortable meeting, where executives and colleagues outside of the cost management team are confused how to understand the results and/or have low confidence in the results. Conversely, the cost management team may feel frustrated that executives are not listening to them or do not trust their conclusions.

What is the solution? The short answer is that the product cost management team needs to better educate their audiences, not only on their results, but how they got to those results. In addition, it is incumbent upon their colleagues to be willing to learn, and invest the time to become conversant in the terminology of cost management just like they would in other function areas, e.g. product development, purchasing, finance, etc.

Having served a myriad of clients in the cost management space over the years, I thought it would be helpful to provide a framework that allows non-experts in the space to characterize and understand cost management modeling by answering a few simple questions.

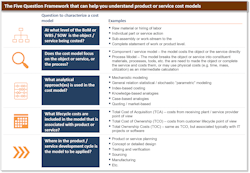

The figure below shows the five questions by which most cost models can be understood. The goal is to provide a primer that can be quickly read by executive management to understand costing analytics.1. At what level of the BoM (bill and material) or WBS (work breakdown structure) is the object or service being costed? – It is important to understand what the cost model is actually focusing on. For example, it could focus on something as deep as the pricing of the raw material in a product, or the model may target other end of the spectrum. That is, the cost model may not care about resolution below the cost of the full system such as a jet fighter plane or the full statement of work of a large service engagement.

2. Does the cost model focus on the object or service, or does it focus on the process? – Some models will focus directly on costing a final component or service, based on parameters of those objects of interest. Other models will break the manufacture of the component into its constituent resources that are needed, such as masses of material, time on machines, labor content, capital tooling, etc. In this case, model will often focus not on the final cost, but on intermediate values such as time, mass, utilization etc.

3. What analytical approach is used in the cost model? – While it is true that a cost model for a product or a service might use multiple methods of modeling, and often does, typically a given model relies most heavily on one technique. There are many different types of techniques for generating the final value of cost or intermediate values (time, mass, etc.), but most of them can be aggregated into five or six basic classes of modeling techniques. In fact, these general techniques of modeling are not unique to the world of cost modeling, but general ways that anything might be modeled.

4. What lifecycle costs are included in the model are associated with the product or service? – From what vantage point are we viewing the cost? For example, if one is purchasing a part from a supplier or a service from a provider , they should be looking at the Total Cost of Acquisition, which is the cost to deliver that service or product to the next receiving point. Another viewpoint is the customer himself, often referred to as Total Cost of Ownership. (or in IT and software, it is transposed as “Total Ownership Cost”)

5. Where in the product or service development cycle is the model to be applied? – There are different modeling methodologies and expectations depending on where in the lifecycle one wants to use the model. There is typically also a strong correlation between how much information is known about the product or service versus the level of resolution the model will provide.

This will give the executive a simple framework to use when working with their cost management colleagues that should help lead to a productive discussion on both sides.

Eric Arno Hiller is the managing partner of Hiller Associates, a consulting firm specializing in Product Cost Management (PCM), should-cost, design-to-value and software product management. He is a former McKinsey & Company engagement manager and operations expert. Before McKinsey, Hiller was the co-founder and founding CEO of two high technology start-ups: aPriori (a PCM software platform) and TADA.today. He has also worked in product development and manufacturing at Ford Motor Co., John Deere, and Procter & Gamble. Hiller is the author of the PCM blog www.ProductProfitAndRisk.com. He holds an MBA from Harvard Business School and a master’s and bachelor’s degree in mechanical engineering from the University of Illinois Urbana-Champaign.